CNC TECHNOLOGY AT FRESNO CITY COLLEGE

By Maryann Valentine

Jorge Perez is a manufacturing student at Fresno City College, and has been working with routers for quite some time now. Excelling in everything he does with a creative twist to each project he completes, Jorge has become a true machinist with the help from his instructor, Mark. His Instagram account, @Jorge_CNC, showcases the captivating projects he has complete thus far during the program.

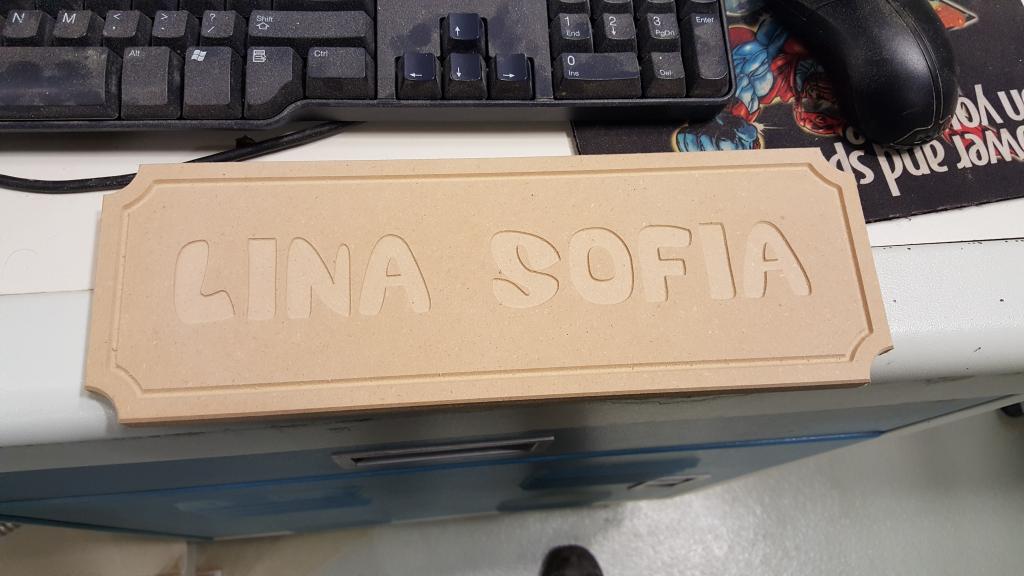

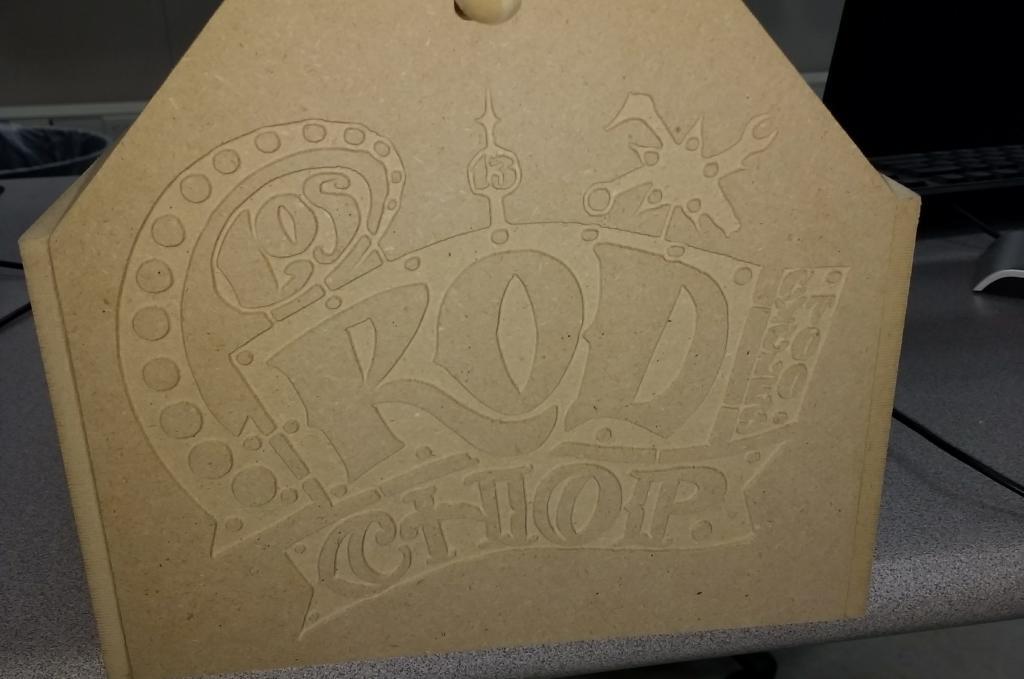

Jorge spoke highly of the manufacturing program at Fresno City College. “It is such an advanced program compared to others. The instructors focus on allowing each student to get a lot of hands on action with the machines. We aren’t just learning by watching or being taught by step by step instruction manuals. We are taught to try on our own, mess up a little, but most importantly, learn from each other. It’s an awesome program to be a part of.” After the students complete the CAD/CAM software training at the beginning of class, Jorge said this is where the students creativity is key. “We all focus on making something unique to ourselves, rather than perfecting the exact same prototype twenty-something times. Our instructors basically allow us to use our creativity to come up with anything.” Fresno City College allows the students to make about 5-6 projects a semester using different kinds of plastics, where they then can move up to more advanced materials that make and engrave signs. The students are encouraged to think outside the box… the possibilities with their Techno CNC router are, indeed, endless.

“I find it so helpful that our instructors allow us to do our own programming, as well. At other schools, the instructors usually do the programming for you, or go over it with every single student individually. Instead, my instructor allows us to practice on our own. We let other students teach each other, which is awesome! It helps us all to learn the machines, as opposed to just following the directions on how to program. Our instructor believes that being able to teach one another is the key to becoming a true machinist.”

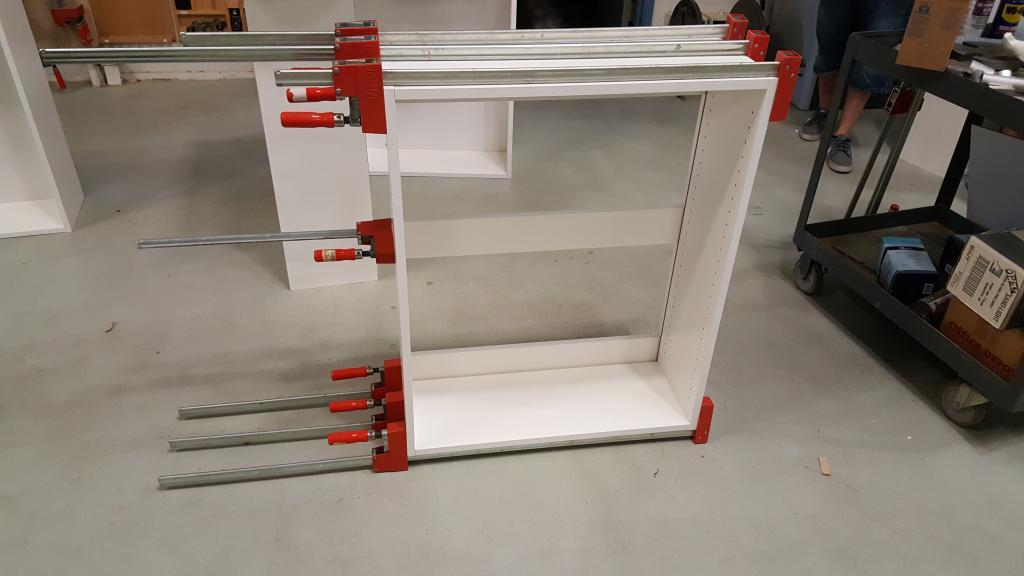

Perez spoke about the different levels of the class, and how the class improves throughout the semester. They start with easier projects, but then advance to more advanced classes where their projects become harder and their learning becomes clearer. “We recently used a 4×8 piece of melamine to create a cabinet of some type. It’s tricky because we only have one piece to do the entire project, correct. That’s the tricky part about manufacturing- everyone makes mistakes, so when we are tested on our knowledge of the machines/program itself, it is super nerve-racking to know that anything is possible.” Perez shared a tip he recently learned from a personal experience using the Techno CNC in class. “I found it hard to know where my part was going to move on the table. I learned that the router is very forgiving… The machine will allow you to fix your mistake… which was one of the greatest tips I could have learned. I simply hit the pause button, reset the part to go back to 0, repositioned my part, and boom. I was able to save a lot of time and material by using this one simple trick time after time. You just have to slow down when you make a mistake, and the machine will fix itself for you.”

One of the main goals of the program study is to become an instructor yourself. Perez’s instructor has taught his students the importance of being able to teach someone else exactly what you are doing, and “then, you are a real machinist.” The program focuses on making the students step outside of their comfort zone, and allowing them to practice, learn, and study with the help of other students. The program is focused around the machines, the software, and learning the correct way to do things, rather than following an instruction manual step by step. The students are also allowed to bring in their own material from home; they are not limited to what the school provides them with.

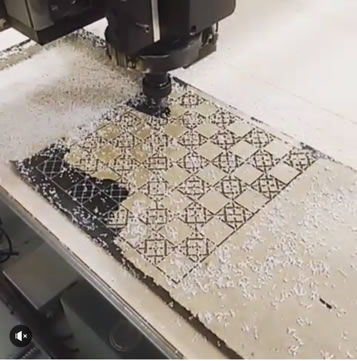

Perez went on to tell me about his latest project, and the most challenging part about completing his final: a complete chess set. “My final project for advanced class was to make a complete chess set from scratch. I couldn’t figure out how to design it. I was determined to make mine unique and not look like the rest of the class. It was challenging. I cut out a lot of pieces but didn’t have a board, just yet. That is where our Techno CNC router came into play. I used a 3 quarter inch acrylic piece, and router the entire board using the CNC. The most challenging part was that I wanted to make a board that went with the geometry of my chess pieces themselves. I designed each piece from the ground up. I gave each piece extremely sharp corners, and wanted the board to reflect upon that. With that goal in mind, I stared at the machine for a while to see how it engraved, and to see what tool paths were available to program. It hit me finally, and I was able to figure out what speeds would cut on the acrylic. I used the 4×8 router, which involved tool changes, as well. I had to do a quarter inch straight bit to cut it out, plus an engraving bit to engrave on the board. It truthfully came out awesome, thanks to the Techno CNC router.”

“We all love the Techno CNC router in class. The machines are by far one of the better routers I’ve ever used. They are all really fast! I have never been limited when using my Techno CNC router; the possibilities are endless, especially with wood. feel like the quality is superb for what they do… and especially for the price. Amazing results, and I would highly recommend this router.